“The conditions were pretty awful, to be honest,” says Thomas Laakso, referring to his time testing ski prototypes on Mount Hood at the tail end of this summer. He continued, “but that’s a good thing for us. Skiing variable conditions like crud helps evaluate what works and what doesn’t a lot faster.”

As the VP of Product and Operations at DPS Skis, and a 20-year veteran of the ski industry, Laakso has taken more than a few pilgrimages to endless season outposts like Oregon’s Timberline to test skis. “We’re close to a final design—the last three days were focused on A/B testing of two similar models, to pick the best one,” says Laakso, holding back on further specifics. “We just feel fortunate to be skiing and to be able to test at all, under the circumstances.”

Laakso (pictured above) cut his teeth as a product manager at The North Face in the late ’90s, including work on a jacket that won Time’s Innovation of the Year. Five years later, he migrated to Black Diamond to become the ski category director. After 12 years and 35 patents, Laakso took a hiatus from corporations to help launch Mountain Hub, an avalanche safety startup. Most recently, in 2018, Laakso joined DPS. It’s fair to say that there are maybe a dozen people in the world that know the skis as well as Laakso.

“Honestly DPS feels a lot like a modern startup, at least culture-wise,” says Laakso. “We’re small and lean. We test products fast.” The downside to being nimble, is less supporting infrastructure. “But that’ll change,” Laasko adds. “For context, we’re the biggest ski manufacturer in the country, but at just 15 years old, we’re still smaller than many European brands.”

Practically speaking, the DPS factory employees 35 full-time workers that make skis year-round. While the brand declined to share the exact number of skis it produces annually, its annual revenue was estimated at 18M last year, which likely means tens of thousands of pairs. Still, this is considerably smaller than a number of European manufacturers who have historically been race-driven brands with much larger markets. Demand for skis this winter has, according to DPS, exceeded expectations.

When asked about the biggest differences between DPS and competitors, Laakso was quick to respond: “We can design, make a prototype, test it on the slopes, and iterate all in the same week. Not many ski companies are able to do that. With the Wasatch out our backdoor and our production facility here in Utah, we also have more control over the process. We’ve looked at going overseas but couldn’t create the same quality, so we’ve stayed put.”

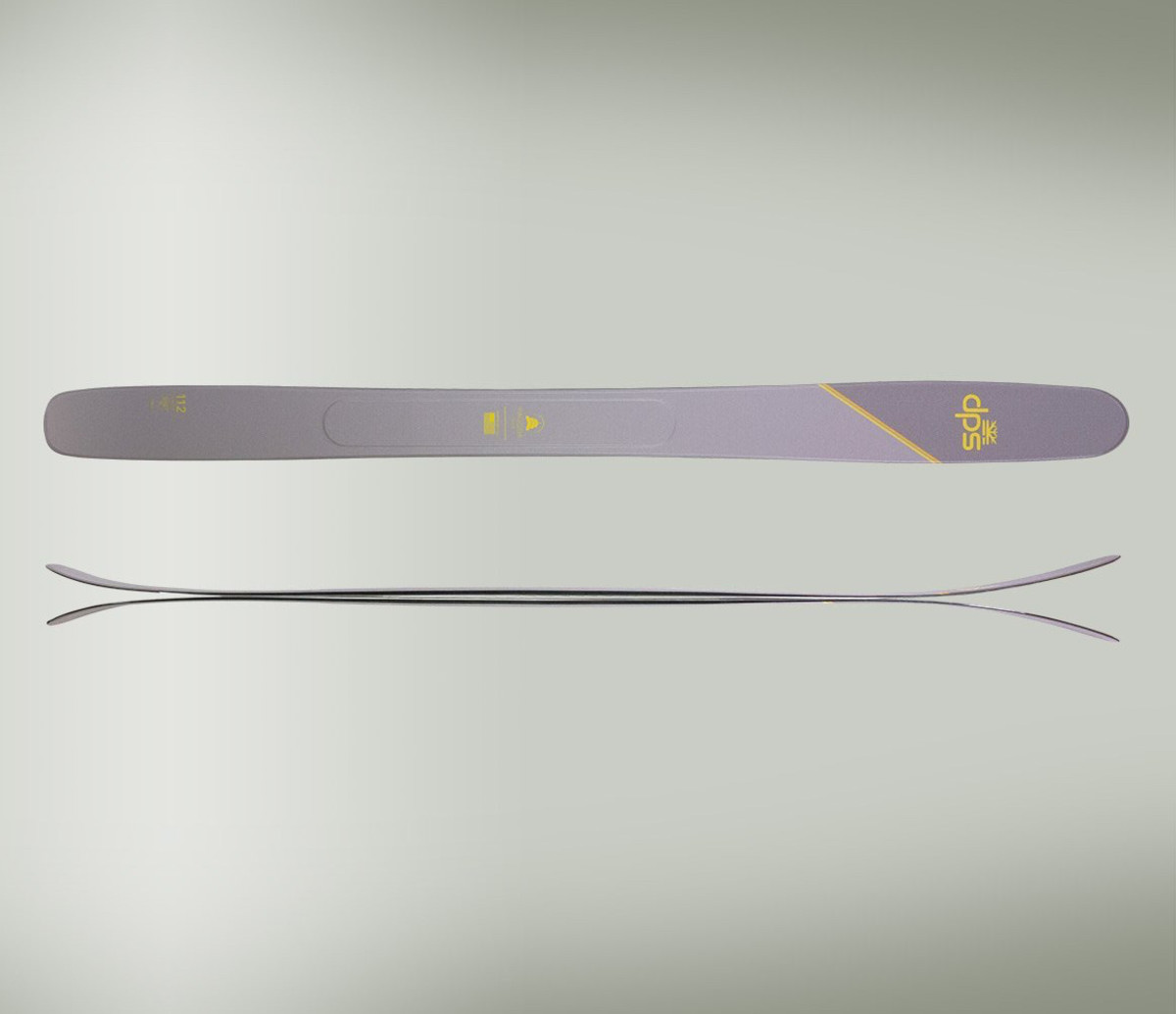

Laakso was brought into DPS to create internal structures, establish a long-term strategy, and find ways to reach new customers in a highly competitive industry. “We’re either the biggest small ski company in the world or the smallest big ski company, but size doesn’t always correlate to a great product,” laughs Laakso. “Innovation often comes from newer players in a space. Big brands have started to take note of us. The Rossi Soul 7—arguably the most popular ski in the world—took direction from the design of the Wailer 112 RP and is a spitting image of it, then crushed it in volume.”

As part of the three-headed senior management team driving the bigger picture of the company, Laakso works with ski designer Peter Turner, a DPS co-founder, and Nick Pascoe, a young Kiwi and lead product manager, to oversee product creation and R&D. This includes the new Pagoda ski lines, Phantom waxless glide launched three years ago, and a rapid transition to produce PPE face shields during this spring’s outbreak of the COVID-19 pandemic.

“We make a lot of different products, but the process is always the same,” says Laakso. “A lot of brands talk about one shape or one material that makes their skis great, but that’s not how we see it. It’s not just great carbon fiber or sweet shape that makes a good ski. Just like you need all the right ingredients to make a good soup, you need a complete recipe to make a good ski. We’re a high-end speciality kitchen compared to a commodity cafeteria.”

From this mentality came the Pagoda lines, made with new innovations in the wood cores, new shapes, and patented carbon-fiber constructions. This paradigm also drove DPS’ off-season project: face shields for frontline workers. Wanting to find a way to help those in need as well as keep their factory running and avoid layoffs, Laakso and his team designed and produced over 80,000 protective shields and their effort is still going.

Yet, despite major innovations in the last few years, Laakso believes the best is yet to come. “My favorite ski I’ve ever ridden isn’t out yet—you’ll have to wait a year to get a chance to test it,” says Laakso.

from Men's Journal https://ift.tt/35Hzsvo

No comments:

Post a Comment